I’ve been busy with a new project!

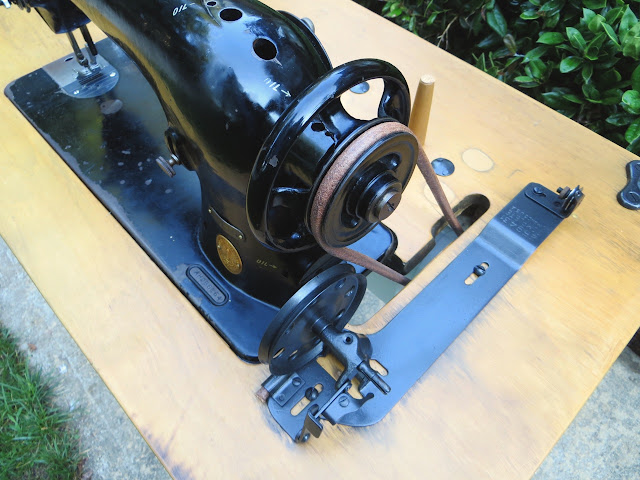

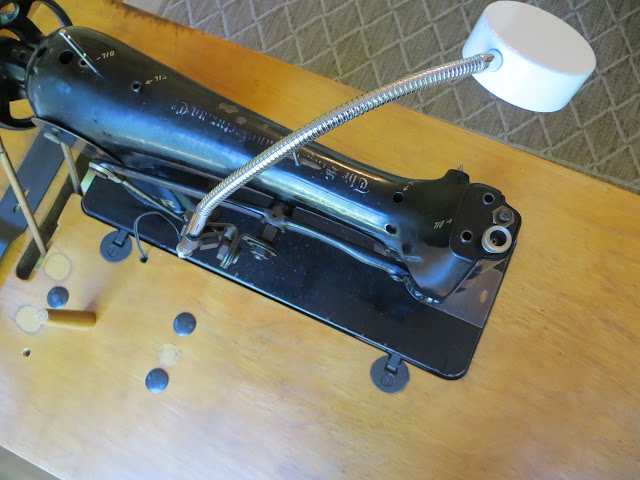

I came across an industrial Singer 31-15 sewing machine for $100 and I went straight away to pick it up. I knew even before seeing it in person that the cords would need to be replaced on the motor. I was going to try and keep the original clutch motor because it’s part of the machine (they’ve been together since 1947!) but after working with the machine for a few minutes at home I realized it wouldn’t be worth dealing with the speed and noise.

In this post I will show you how I restored the table, what parts on the machine I replaced (and why), how I fixed the wires on the clutch motor (for someone else to use it) and how to set-up and install a servo motor under the table.

This project took me 10 days total. If I didn’t have to wait for parts to arrive it would have taken half the time (waiting is SO hard for me)! At the end I’ll break down how much I spent.

Below are several before and after pictures. I love seeing the difference – even I was surprised after comparing!

I first disassembled the table so while the finish was curing for a few days I could work on the machine.

TABLE DISSASEMBLY AND MAKEOVER

To fix the peeling veener on the table I blew wood glue down into the cracks with my air compressor.

Clamp for a few hours (wipe off excess glue while wet). Sand remaining-dried glue.

These are the supplies I used for filling gaps and preparing table for stain.

Mix wood filler and hardener. The amounts specified on the label aren’t precise so I do about 12 parts putty to 1 part hardener.

You only have 5 minutes to work with the putty before it dries – use a putty knife to press into gaps.

While the filler was hardening I worked on the pan that sits below the machine. I wiped it down and sanded off rust/smoothed out the metal.

Sand table smooth. I filled the 3 large holes from the old motor knowing they wouldn’t match up with the new servo motor. I also sanded the drawer and wood spindle for holding the machine up when tilted back.

I taped off the table so I could spray paint the pan on both sides.

I did a coat of primer and two coats of black hammered finish. I love the hammered finish because it hides imperfections really well and it has a nice look.

I used Thompson’s WaterSeal stain in semi-transparent, maple brown color to coat all the wood surfaces. Even though this is outdoor stain I like to use what I have on hand 🙂

Once the table was dry I used a coat of paste wax on all the wood surfaces.

Buffed smooth with my buffer (so handy)! It made the finish silky smooth and beautiful!

Are you ready to get your hands dirty!? These next steps were my least favorite and time-intensive but I knew doing the job right would mean having a nice finish in the end. You’ll want to sand all the rust off your metal pieces to get them smooth. The only pieces I didn’t sand were the bolts/nuts/washers… I’ll get to that.

For the hard to sand places I used steel wool clamped in my pliers.

The bobbin winder and thread stand had a lot of gunk I couldn’t get off by sanding because there was so much detailed pieces so I brought them inside with all the bolts/nuts/washers and gave them a scrub with vinegar. I usually use rubbing alcohol but it’s really hard on my hands. I rinsed the pieces off with water and although I was reluctant to expose the pieces to water it was worth it – so much grime came off. I baked all my pieces in the oven at 200-degrees to dry them off quickly to prevent more rust.

Prep the rest of your stand pieces by blowing off as much dust as you can with your air compressor and then use TSP to wipe clean.

For the heavily-rusted areas I used a rust reformer before priming.

Lay out all your pieces for priming. It can be tricky to get all the sides coated well; do one side first, let dry, flip then paint last side.

Once your primer is dry spray two coats of the finish of your choosing. This gave me really great coverage and the pieces looked amazing!

I bought a sheet of adhesive cork and made a pattern the size of the surface I wanted to cover on my pedal.

The cork is really tacky and won’t come off – now my foot will have good traction!

Give your table about 24 hours to dry before you assemble back together.

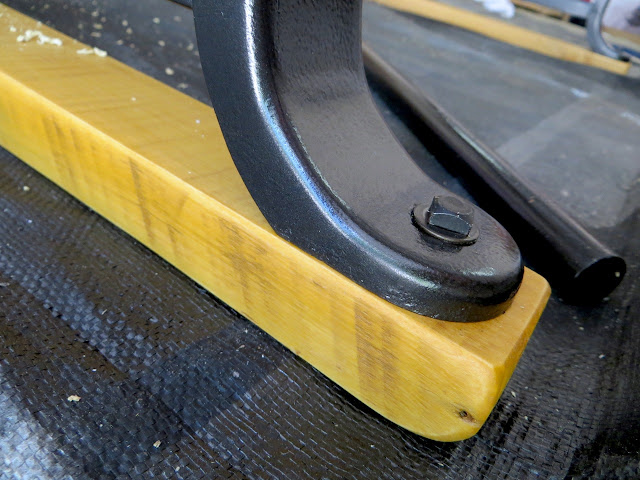

This is when I realized I wanted to keep the metal stand off my floors and that wooden ‘sleds’ would help me move the table by myself. This machine will be in our guest room/Dani’s craft room so it will get moved every time we have visitors.

I was so proud that I bought square black bolts a few months ago (for no reason) because they matched the original bolts perfectly!

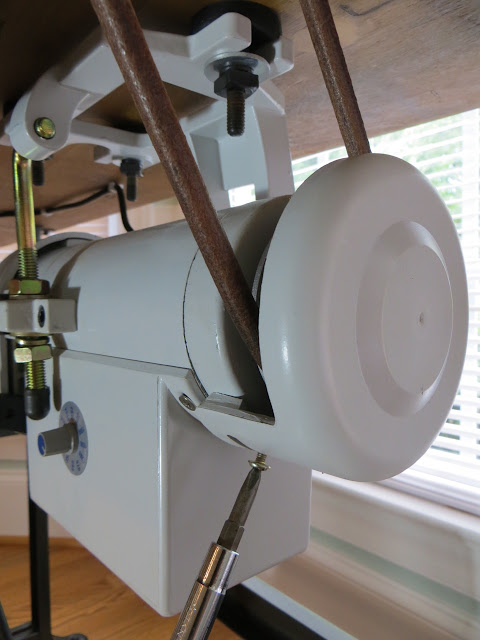

BOLTING THE SERVO-MOTOR TO THE TABLE

Right as I finished assembling the table a package arrived for me! The servo motor I ordered the day before!

Now what? It’s very easy to install but you definitely want to make sure you have it lined up with the groove in your table where the belt runs through – you’ll be drilling large holes for bolts and you don’t want to mess that up!

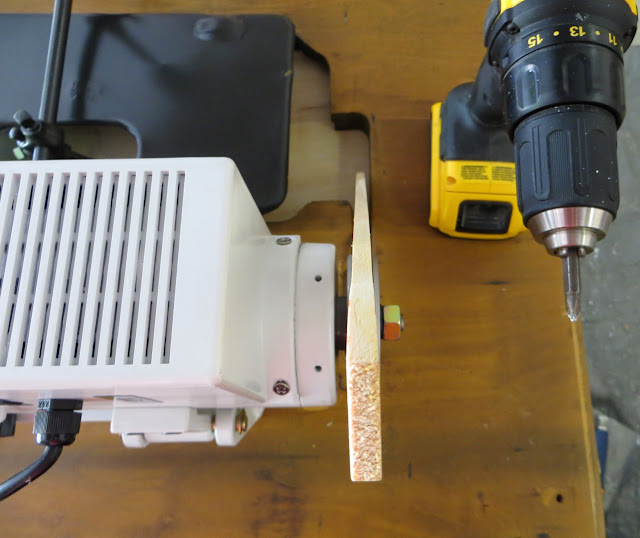

I set my motor up in the position the old one was, then I used a paint stick to rest on the motor pulley and down through the groove in the table to fine-tune the position.

Once I was confident I had the motor where I wanted I marked where to drill for the bolts. Notice there’s big black rubber pads the motor will rest on so give room for those.

I wanted to keep everything as original as possible so rather than using the silver bolts that came with the motor I used the original ones – they were shorter but still longer than necessary.

Drill holes slightly larger than bolts and place rubber pads over each one. You can see where the old holes are compared to the new holes.

Set motor over bolts with washers and tighten nuts.

Pre-drill and screw your on/off switch to the front of your table.

Use the plastic clips to hammer wire to the table. Avoid where the table legs will go.

Now for the machine! Ready!?

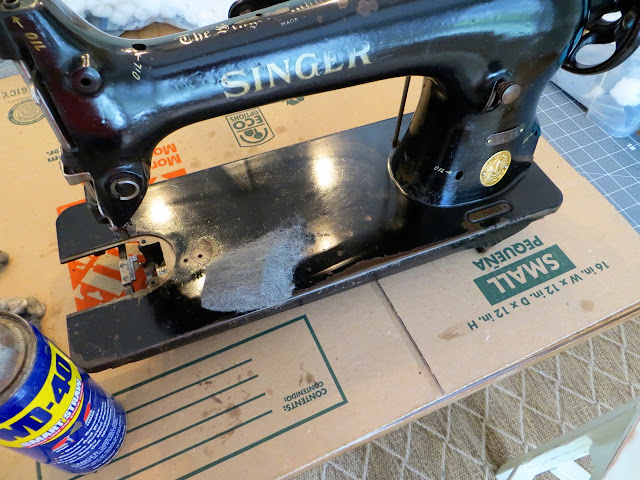

I took as many pieces off as I could to make cleaning the machine easier. I took a different approach to my regular method of cotton balls and rubbing alcohol (it really isn’t good for the finish anyways) and used WD-40 to spray on a ‘0000’ steel wool pad and scrubbed away on the finish.

I used a soft cotton rag to wipe clean. You may want to repeat WD-40 if you feel like you can get more grime off.

For polishing I buffed some turtle wax over the paint.

I soaked all my pieces in vinegar for an hour and scrubbed with a cleaning brush. It really helped loosen grime and helped remove surface rust. I reluctantly rinsed these pieces with water but still did knowing I was going to bake them in the oven to fully dry quickly.

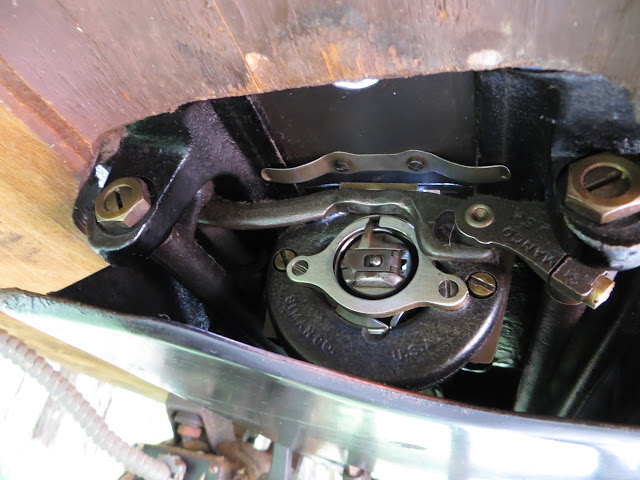

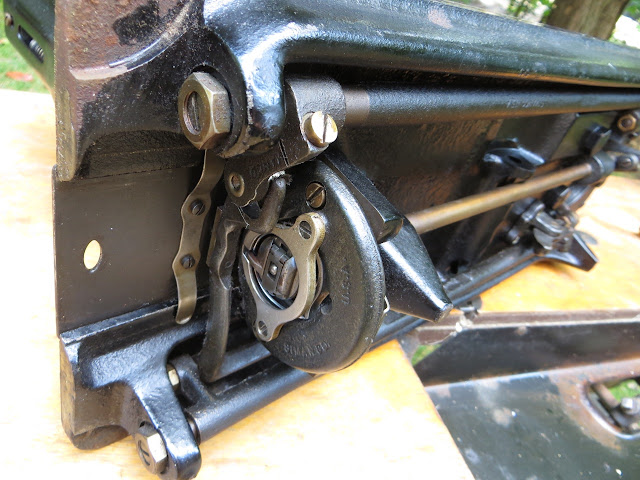

Once my pieces were dry I rubbed some sewing machine oil on all their surfaces to protect from rusting. I put all the parts back on my machine so I could test everything out and see what pieces I needed to replace – if any. If your old belt doesn’t fit you can use your hand to move the hand wheel to see how it stitches and if the thread catches anywhere.

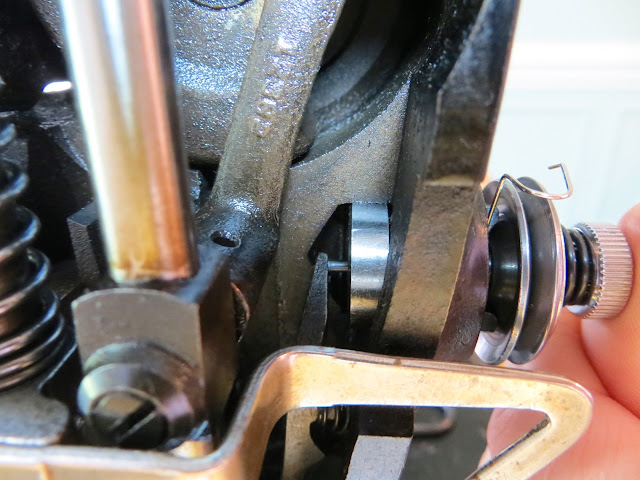

My thread was catching really bad in the hook area and snapping/breaking the thread (regular sewing thread) but with the thicker #67 thread it would snag and let loose really quickly. I used 400 grit sand paper to try and clean up the hook and bobbin to polish smooth – it was still catching. The tension discs and main thread guide (by tension assembly) were really dull and rough – I sanded those too but wasn’t pleased enough. I made a list of what I needed.

MUSTS: shuttle hook (didn’t work), bobbin case, thread guides (all 3), tension discs, needles, thread and leather belt.

I got a little excited and bought a new needle plate and feed dog (wider feed area and marked seam guide), a few extra feet, and a WHOLE tension assembly with extra discs for the bobbin winder.

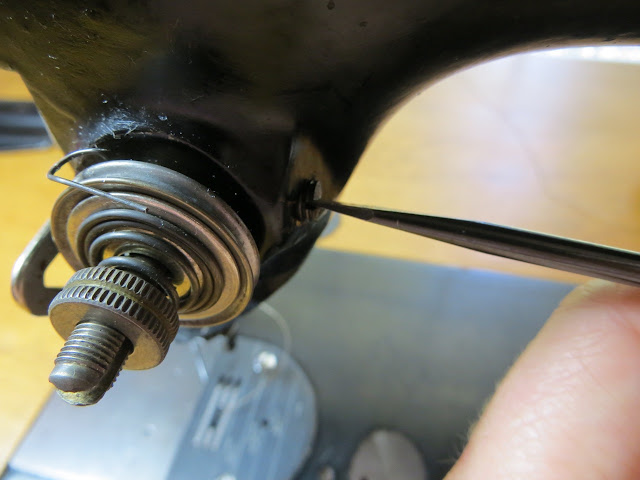

I could have replaced just the tension discs but it was only $5 more for the whole assembly. Before removing the original, take off the face plate with presser foot lowered to notice the gap between the tension rod and the tension release bar. There’s a very small gap – about 1/32″. You’ll need to recreate this gap with the new assembly.

Remove the old assembly by loosening the screw on the side.

Here’s a side-by-side comparison. Notice how much longer the rod is on the new assembly (right) – you need to trim it to fit your machine.

Slide your new assembly in (the opening on the side goes to the left and the spring-arm on top).

Because the rod was so long it kept the discs spread apart.

This is what the rod looked like inside – it was under a lot of pressure.

Use pliers and snip away a little, test, snip more, test, etc. Once I got closer to the length I needed I filed the rest to ensure I didn’t take off too much.

The new rod is still longer than the original but that’s because the assemblies aren’t exactly the same.

I think I still cut too much off – see the gap is closer to 1/8″ rather than 1/32″ (this makes it so the tension doesn’t completely release on my top thread when I put my presser foot up to take my material out – annoying for now – I’ll just have to get a new one)! Oops!

UPDATE: I decided to make my own tension rod and within minutes I found a nail that was just the right diameter and cut off the head and made it slightly longer than the new one I just ruined and it works flawlessly!

UPDATE: I decided to make my own tension rod and within minutes I found a nail that was just the right diameter and cut off the head and made it slightly longer than the new one I just ruined and it works flawlessly!

I put on the new tension discs for the bobbin winder.

Here’s comparing the new thread guides with the old (one of the old ones was missing).

I placed this thread guide hanging down because when it was horizontal my thread kept slipping out of the tension assembly.

Tap the other guides into the top (make sure you’re not putting them in the ‘oil’ holes)!

Here’s my new needle plate/feet dog and bobbins compared with the old. The new feed dogs have a much better grip on the fabric and they pull it through straight.

I attached feed dogs, then needle plate.

I noticed the old leather belt piece for the bobbin brake was really dry and easy to break…

…so I cut a chunk off the new motor belt and replaced it.

Here’s the original hook (left) with the new one. They have slight differences but overall looked promising.

The new one fit into the grooves of the race…

…but wouldn’t allow the race/cover to screw perfectly snug against the machine – this left the machine binding every 1/2 turn. I may attempt to sand it down in areas to get it to work but for now my thread will snag with the original.

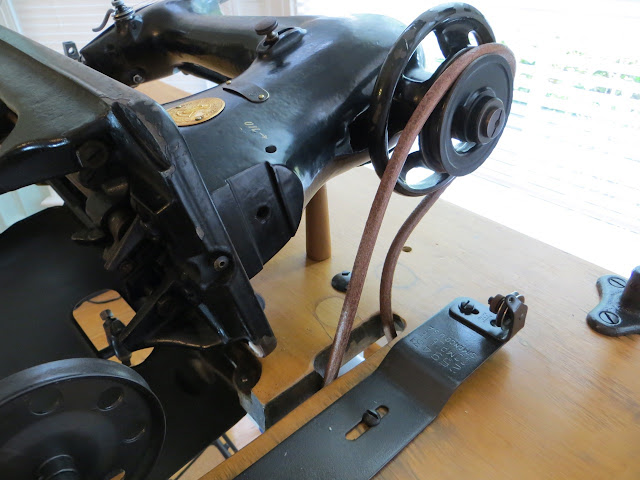

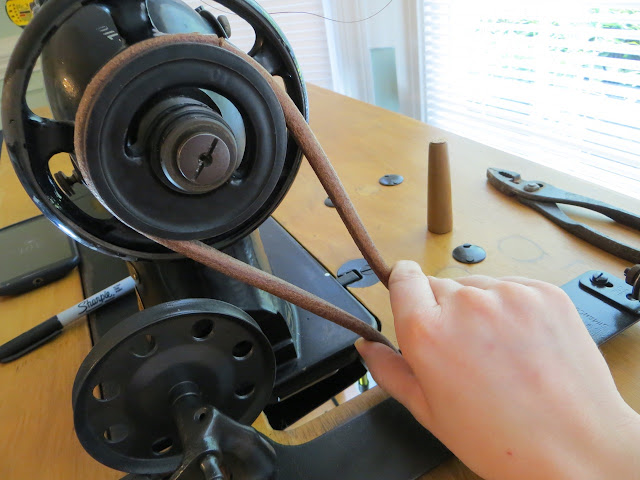

ATTACHING THE LEATHER MOTOR BELT

Here are the supplies needed. Some people use a nail to make the hole in the belt but I find drilling the hole is much easier/faster/precise.

Don’t use snippers because they cut the belt with a triangle tip and you want a clean-flat end. Clean up the original belt ends before you start because they’re usually not very neat.

For my machine I got a 5/16″-thick belt and it sits in the grooves on my hand wheel and motor pulley perfectly.

Wrap the belt around motor pulley and hand wheel tightly.

Mark where they both meet.

Cut directly on your mark with your razor blade.

Make a hole in one end, centered, about 1/4″ down (or half the length of your metal staple). Drill the second hole in the other end.

Put your belt around your motor pulley again and up next to the hand wheel.

Attach staple and crimp ends down tight with pliers.

Set machine back to get belt on.

My belt has too much give to it (you want a little). I lowered my motor by loosening the bottom bolt by the speed dial. If the motor is already in the lowest position you’ll want to cut off more of your belt.

Attach cover over pulley.

BONUS SHOTS:

I made leather circles for the thread to sit on. It looks nice but also keeps the spools in place and adds a noise buffer.

Machine tilted back on wooden spindle.

See the hinges I got for the machine to tilt back on (the originals were missing).

I didn’t have any industrial-thick thread so I had to buy some! I love pretty thread! From Lu Thread (great prices)!

Here’s a test run on the machine with some leather and #69 thread. Runs so smooth and quiet!

My first project was making my baby his first pair of shoes!

He really liked them and my machine, too!

COST BREAKDOWN:

Machine – $100

Servo Motor – $120

Parts, belt, needles, etc – $110

Total = $330

I’m so excited about this machine! It’s only straight-stitch with no reverse. It’s beautiful and I love that it has history and character. Comparing this machine to my top-of-the-line, triple compound feed, self-oiling, “Rolls Royce” Durkopp Adler I am very satisfied (I sold it 6 months ago because it was too heavy & too much machine than what I needed). I love this Singer because it’s smaller and lighter-weight than the Adler and doesn’t have any unnecessary functions to worry about. It’s simple and straight-forward sewing!

I fixed up the manual – download one here.

I just finished a thread organizer to go with the table! Click here for instructions.

I wanted to make use of the bracket on the back of my machine where the original light was clamped. I actually bought this light from the dollar store was surprised with how bright it is. I took of the base it came on, cut the wires so I could thread them through the hole on the table and attached the plug end back on.

It plugs right into the back of my motor…

…so the light comes on when I switch on the motor. I really like that I can adjust the light where I want.

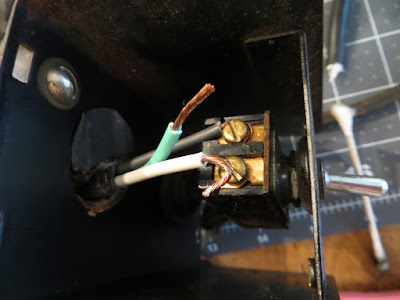

Someone wired an extension cord to the motor switch…

…cut off the original light and left the wires hanging out of the motor…

…and used a lot of electrical tape.

I needed to fix that, don’t you think?

I loosened the wires leading up to the motor…

…opened the terminal box and made sure to take a picture of how the wires matched up so I could put it back the right way.

I loosened the 4 large bolts holding the housing together and found a lot of dust and lint, wow!

This is part-way cleaned up inside – I used my detail vacuum extensions and cleaned it up real nice!

I bolted the housing back together to tackle those loose light wires. I cut them a little shorter and removed 3/4-inch of the covering on each wire…

…and screwed a wire nut on the ends. This makes me feel so much better!

Next I attached all the wires back on the terminals and closed up the box.

Next was the on/off switch and taking that extension cord off. Notice how the green ground wire is cut short and not grounded?

A clean slate to work with!

Here’s the other side where the motor wires attach to the switch. We’ll want to wire in the new wires so the black and white match up to these wires… but on the other side (thanks to my Dad and brother for helping me make sure I was doing this right).

I used a 6′-long extension cord, cut the end off and scored around the rubber sheathing to expose about 2-inches of the internal wires.

I stripped 3/4″ off the stranded wires and twisted the ends tightly.

I made sure to attach the wires so they corresponded with the ones on the other side for the motor. Wrap wire around your screws from left to right so when you tighten screw they won’t slip out.

The ground wire screwed right onto the metal housing.

I attached the metal clip-thing that was on the old extension cord – it holds the wires in the opening and clamps them down.

Rust – eek! I cleaned it up the best I could with a wire brush and WD-40.

Much better – it makes me so happy!

No more light wires hanging out either!

57 Comments

Absolutely great post on the steps of this project. The photos really tell the story. Cannot believe how fast you got this done. I did not know about being able to clean rusty bolts with vinegar. Will have to try that, as I'm getting ready to refinish my porch glider. Thanks so much for sharing this information. Great job!!

August 2, 2016 at 9:16 amVery Nice restoration. Great Pictures. I have several industrial machines in my herd and have faced some of your challenges. I need to reglue a top similar to yours. Nice patching of the old motor holes .. the whole rig is probably much lighter now that you converted to servo motors.

Visiting from the Leatherworker site.

Lee

August 3, 2016 at 1:00 pmHi Lee! The hardest part about fixing the top is dissembling everything. It is MUCH lighter thankfully! I'm used to my Adler 867 I had before this and the head of the machine was twice as heavy as this one (if not more) – I love that I can pop it off of the table within seconds for moving even easier!

Good luck with your projects! 🙂

August 4, 2016 at 9:30 amVince in Perth Western Australia

August 21, 2016 at 3:53 pmThanks Dani for all the effort writing up your blog.

A tip that I remember from a master knifemaker when he was demonstrating making leather holsters is to drill leather using a nail in the machine the same way you would use a drill bit.It parts the grain of the leather rather than cutting it.

Good luck

Vince

Thank you for the tip!

August 30, 2016 at 7:33 pmDani – thanks for sharing all the details of this project. I'm buying a very similar 31-15 and will likely be doing the same renovations you did. I've looked at those servo motors on ebay and they seem just the ticket. Which model did you buy? Is it 3/4hp? Thanks Steve

October 27, 2016 at 2:57 pmHi Steve! The motor I bought was off Amazon and it came the next day (on the East Coast)! I've been very happy with it – it looks identical to one I bought from a shop a few years ago that buys/sell only Industrial Sewing Machines. The specifications say it's 3/4 HP.

https://www.amazon.com/gp/product/B001VK9YH8/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

Good luck! I have been really happy with this machine and, unfortunately for my husband, it might be saying in our formal dining room so I can look at it everyday! 🙂

October 28, 2016 at 9:46 amDani – The 31-15 I picked up a couple months ago was pretty beat up and best suited as a parts machine. But yesterday I picked up a very nice original 31-15 complete with a nice table and original clutch motor. Now that you've been using yours for a while, I was wondering of you have any other lessons learned, tips or recommendations. If you were to buy another servo motor, would you buy the same one? If possible, I'd like to find one that uses the original mounting holes, but maybe I'm wishing for too much. Thanks Steve

January 1, 2017 at 10:21 pmHi Steve! I've been extremely happy with this machine and there's no way I'll ever want to sell it! Not only has it sewn through everything I've put through it without whimpering or straining… it is stunning to look at! I wouldn't change a thing about this machine, although having a reverse option would be nice (but there's ways around that of course). I'm surprised at how well fabric and layers feed through the machine, especially since I'm used to having a triple-compound-feed Adler as my first Industrial machine! I can't think of any other tips or recommendations to tell you the truth! I have only good things to say about the servo I bought. I can see your point about wanting to use the original holes on the table – I don't know if all the servos have the same bolt orientations or not but I guess it's worth looking around. If you do end up drilling new holes, the Bondo wood filler I used is amazing and cures very quickly! No cracking yet and I don't forsee it in the future either – super solid. Let me know if you have any other questions!

January 1, 2017 at 11:27 pmThanks Dani, glad to hear it has proved it's worth. My machine has a different clutch motor than yours did. After looking closer at it and the servo motor, I think it will bolt on using the original holes – Yay! Thanks Steve

January 2, 2017 at 10:05 amThat would be great to use the original holes! I hope it works out! Let me know how you get the machine set-up and how you like it!

January 2, 2017 at 10:06 amHi Dani, came across this blog by chance and was mesmerized. I have a 95-10 that I refuse to let go. I recently purchased a servo motor CSM-550-1, but was hesitant about replacing the original clutch motor myself. Your step by step gave me hope.

July 28, 2017 at 10:30 amWhy did you repair the old clutch motor if I may ask? Just because?

Hi Sevil!

I'm so glad you wrote! There's nothing better than knowing I gave someone hope! It really is so easy to install a servo – I just did a 2nd one: https://www.theprojectlady.com/2017/07/singer-111w152-industrial-sewing.html

The hardest thing about installing a new motor is getting the right belt to fit. I used an adjustable v-link belt I took off my lathe and it was so great to take links off as I needed to get it JUST right.

I fixed up the old clutch motor because it works perfectly – just needed some help. I didn't have any plans for it and hope to sell it for cheap to someone who could use it. Almost a year later and someone is actually coming to *hopefully* buy it today for about $25 🙂

Let me know how your project goes!

July 28, 2017 at 10:33 amDo you have an idea what the machine head weighs/ I am considering a similar project with an ancient Husqvarna.

September 26, 2017 at 9:10 pmHmm… I'd guess 50 lbs. It's much less than my Singer 111w and was very manageable to remove from the table and pick it up off the ground.

September 26, 2017 at 9:12 pmWhat an inspiring post Dani, thanks for sharing all the details, very useful info, as I really need a servo asap. I love that the first thing you made was your son's bootees, and they look terrific too, as does the machine after all your hard work. I like the tip about cleaning it with WD 40, and will do mine tomorrow. I recently got a 331k5, it doesn't look quite as good as the old black ones, (it's silvery blue and not quite so rounded) but being late 50's early 60's, it still has character (and a lovely wooden table with cast iron treadle type base and the very old fashioned Singer and iron mesh patterned foot plate. I really like your spools stand too, amazing idea to stand neatly at the end. Congratulations on a super job all round 🙂

October 3, 2017 at 8:30 pmHi Jessica! I'm glad you found my website and that this post is helpful to you! Thank you for the kind words! I wish you luck with your 'new' machine – it sure feels good to fix these old machines up!

October 3, 2017 at 8:34 pmProfessional sewing machine person here. Fantastic rebuild! You've done a marvelous job.

January 16, 2018 at 6:38 pmThank you very much!

January 17, 2018 at 9:51 amI just picked up a 31-15 with its original table at an estate sale, and I can't wait to get started with the restoration. Thank you thank you thank you for this guide!

February 2, 2018 at 10:11 pmYou’re welcome! Did you get a good deal? What do you plan on making with it? Best of luck with the restoration!!

February 3, 2018 at 4:56 pmYou have done a really amazing, detailed job! Inspiring! Thank you for sharing.

February 9, 2018 at 10:31 pmGreat job.

March 12, 2018 at 7:28 amDoes the motor goes slow enough for tight corners? like real slow?

Yes, the motor helps keep the speed down, and the more you use a machine the better you get at feathering the pedal.

March 12, 2018 at 7:30 amI was just given this sewing machine because I work with leather, it’s great. I have several pieces with it and it is simple to work on. This was converted to electric and just needs a little cleaning. This is the perfect sight for me to find so I can get familiar with the function of a great old machine. Thank You

March 3, 2019 at 6:55 pmI’m so glad you found my page and that it’s helpful for you. Lovely machines – enjoy!

March 4, 2019 at 7:17 amAmazing job!!! Thank you for sharing your hard work 🙂

August 28, 2019 at 6:21 pmI just came upon your site as I was searching for oiling instructions for my 31-15 singer machine. Your machine looks top notch and I’m sure runs like a charm. I worked for a tailor in 1973 and that was all we used. I was able to purchase my own second hand 31-15 in 1974, and have been using it ever since. I wouldn’t trade it for anything. I must say all your hard work has given me motivation to tackle my own. Yours is a show piece. Thank you for showing all the details. Happy Sewing, Merrily

November 6, 2019 at 8:15 amHi Merrily! Thank you for the kind words! They are lovely machines aren’t they! Best of luck if you decide to tackle the beautification process.. it sure feels good when you’re done!

November 6, 2019 at 12:30 pmI have a Singer industrial 31-15 machine. It has a broken thread guide. I got a new one but I cant seem to get the old one out. I oiled it. It moves in and out but it wont come out all the way. I don’t see any screw near it. I would appreciate it if someone could give me a solution. Thank you.

November 10, 2019 at 10:31 amNot sure what to say. . . Wow! seems to cover it. Almost makes me wish I still lived in NC (almost. . .). I love those old solid wood tables. Looking at a 31-15 right now, but slightly newer model with reverse and, unfortunately, the junky-looking laminate-over-particle-board table from the 60s.

November 27, 2019 at 2:55 pmthis is amazing! I have a Singer 31-15 and need to buy a replacement presser foot. Where did you source your new machine pieces from?

February 11, 2020 at 2:55 pmI shop mostly on Ebay – I’ve always had great luck!

March 13, 2020 at 1:06 pmYou’ve delivered a very detailed and comprehensive renovation story of your 31-15. Bravo. I recently bought one out of a local hospital where it spent its life making bed sheets and linens so the wear has been minimal, and as I like to see age, all it needed was a good cleaning and oiling and a good cleaning/repair of the bobbin winder which is two separate pieces, perhaps from an older machine. For removing layers of dried oil and yellowed lacquer I tried several products and discovered that Methyl Hydrate on a soft cloth works wonders if you aren’t worried about removing the lacquer. It doesn’t seem to harm the decals or the paint! I follow up with a plastic polish (I use Novus but I expect any automotive polish would work and protect well) I wasn’t going to replace the clutch motor as I’ve learned to feather it except for those times when it ‘gets away from me’ 🙁 but after reading your article, I just ordered one! Thanks again.

February 25, 2020 at 6:53 amHi Chris! How did the servo-motor installation go? What do you think of it? I insist on having one on all the machines I fix up! 🙂

March 13, 2020 at 1:05 pmhow did you get the new tension assembly in its a little wider it got stuck and hard to get out. what did you do? your detail pictures were great and informative. maybe where did you ordered your parts, or the numbers of your part would help. any little thing would help thank you for your time christine p.

April 17, 2020 at 9:41 pmI hope you got the tension assembly out – I would probably take off the tension discs and everything, thread a nut onto the threads of the assembly and use that to try and pry off – I’d use monkey pliers. I don’t recall where I got parts but I usually buy parts on Ebay. I believe I also have links in the blog post. Good luck!

November 5, 2020 at 8:23 amTHIS IS GREAT! I am right now in the process of restoring my 31-20 machine which is very similar. My son owns a sandblasting and powdercoating business and will be refurbishing my table legs. I have a few parts to order too, and just got an original 1939 (my machine year) parts manual off eBay. I would like to get a few more bobbins, and still looking for the base of the thread stand… I am replacing my power switch with an old bakelite round switch (I wire lamps and electrical as a hobby). My gooseneck light is getting a milk glass shade, and still need to fabricate a drawer. What kind of presser foot do you use to sew leather? I am keeping the original motor on my machine, as it runs, and is just fine to have out in our shop where the boys work on their cars. I plan on sewing upholstery with my machine. I love old sewing machines….they have each their own character. So very happy that you posted this online, because it encourages me to continue with this resto project!

April 20, 2020 at 11:54 pmSo glad my post encouraged you! I’d love to know someone who could sandblast and powdercoat stuff for me!

July 4, 2020 at 3:35 pmDo you still have the manual for this machine?

May 9, 2020 at 4:42 pmYes, here it is: https://drive.google.com/file/d/1Ju1b_ajVhXIaf9j-pbKuAU4n7mTSQcoF/view?usp=sharing

November 5, 2020 at 8:20 amhttps://drive.google.com/file/d/1Ju1b_ajVhXIaf9j-pbKuAU4n7mTSQcoF/view?usp=sharing

November 5, 2020 at 8:27 amI ended up with one with the centennial tag, complete and the table etc looks just like yours, everything is in fantastic shape and previous owners made a wooden cover to cover the machine when not in use, I have owned it like 10 years or so but have never used it, I did manage to buy a huge bunch of needles for the machine, it is a very neat machine and I speculate they used these during ww2 to make items for the military? maybe bed sheets or?

May 13, 2020 at 12:47 pmI have a mix bag of several other Singer sewing machines different models from this time frame, they were fun to collect until they took up to much space.

Hi Dani,

December 8, 2020 at 2:16 pmCame across your posting here as I was doing some research into vintage sewing machines. I’m curious what you thoughts are in regards to different machine attachments. I know there are a couple options for low shank domestic machines (zigzag, button hole) but when it comes to high shank industrial machines are there attachments like these available? It seems like the industrial models are very “specific use oriented”. What’s your opinion on the need of such attachments even? I’m pretty green when it comes to sewing, and am conflicted currently between an old school industrial machine and a heftier vintage domestic model. Thanks for your insight!

Hi Zach!

I love having as many feet attachments as I can! I sold the 31-15 before I looked into buying too many extra feet but I did have a couple. With my current-new industrial I bought I got a pack of 25 feet for a great deal on eBay. I’ve used probably half of them in the last year. They can range from teflon (to slide over vinyl/leather easier), narrow foot, zipper foot, overedging foot, etc. Some of them help you keep your stitching right where you want them because one side hangs off the fabric while the other rides on top of the fabric while you do nice topstitching. I’m sure many people don’t buy new feet because they think they can get away without them. I know how much of a difference they make when you want neat/straight stitching, but they also can make sewing certain things easier.

I personally love industrial machines… they will do pretty much anything you ask them to do without any fuss. My industrial machine is what I use 99% of the time because it’s always setup and ready. I have 2 others, a computerized Pfaff that is awesome for fine/detailed work and an old Singer 201 that I use primarily for making buttonholes (the attachments for these old machine are AMAZING! and I refuse to ever get rid of this old machine because the attachments are so useful). Now that I’m thinking about it, you should definitely look into a Singer 201… they’re beasts and are usually pretty easy to find and the attachments are available on eBay (definitely get a ruffler and buttonholer (with templates).

December 14, 2020 at 7:56 amAmazing job! This is giving me inspiration to find an old machine and to restore it like this. I don’t have a lot of money to spend but if I can put in some elbow grease like you did I hope to have a nice machine like this one someday.

April 15, 2021 at 7:03 pmThank you! Yes, I think you can find these machines for around $150 if you’re patient (and lucky)! They’re a nice-smooth machine compared to the larger-walking foot models around the same time 🙂 Good luck in your quest!

April 16, 2021 at 8:22 amHi Dani,

April 26, 2021 at 2:33 pmWhat an awesome job! I just purchased a 31-15 and came upon your blog after doing a google search. I have ordered a servo motor as it hard for me to sew slowly with the clutch motor.I would like to download the manual, but when I click on the link it says “sorry, the file you have requested does not exist”. Have you removed the manual or is there a new address to access it?

Please keep posting articles, your work and enthusiasm is amazing.

Hi Michael!

I’m sorry the link isn’t working – I fixed it and it should be working now. I’m so glad my blog about the machine has been helpeful – I hope you get the clutch installed successfully – it’s pretty easy!!

April 26, 2021 at 3:48 pmHi Dani,

May 12, 2021 at 5:49 pmThanks for fixing the link for the manual, I was able to get a copy. I am sending you a link to a company that makes and sells electrical cords of many different styles and colors,in case you ever want to upgrade your machines’ cords. My 31-15 came with the original Singer lamp, and it needed a new cord so I went searching and ran into this company. Here is the link: https://www.colorcord.com/, I hope you find it useful. I have one more question for you, do you have a guide and/or source for needles,for my model, and do you have a guide matching needles to thread size?

Keep up the good work. When I get around to rehabbing my machine, I will send pictures.

Thanks again,

Michael

Hey Dani,

May 28, 2021 at 5:42 pmI am upgrading a singer 31-15 I found using the servo motor and process you did. My question is involving the belt and original tensioner.It looks as if you are not actually using the original tensioner and have also had to modify the holes In The table that the belt passes threw. Is this correct. I thought i would check as i am noticing that run in the original openings the belt rubs on the table top. And if I cut the table,the belt will no longer contact the original tensioner. I am ok with this but figured I’d ask before cutting since I know your machine is working as expected and I’d like mine to aswell. Thanks

Hey there! The only alterations I had to do to the table to make the new motor work was drill new holes for the bolts – I filled in the old holes with Bondo (wood filler). With the table upside down I set the new motor on the table to figure out where it needed to set for the belt to clear the center of the opening in the table. Hope that helps!

May 29, 2021 at 12:55 pmI’m looking at one of these machines and it’s nice to see another badass handy lady! I’m not quite at your level so I’m very impressed. Thanks for showing all your steps! This is an amazing post!

November 18, 2021 at 6:18 pmI love mine and have used it for years. Very cool! Great ideas. Impressive!

July 15, 2022 at 2:12 am$330 + 10 days of your time, that’s not a trivial investment, but the results are satisfying, after all.

February 4, 2023 at 10:41 pmDo the feed dogs drop on this model?

May 8, 2023 at 8:32 pmI’m sorry but I can’t remember. I don’t have the machine any longer to check 🙁

May 19, 2023 at 7:04 am